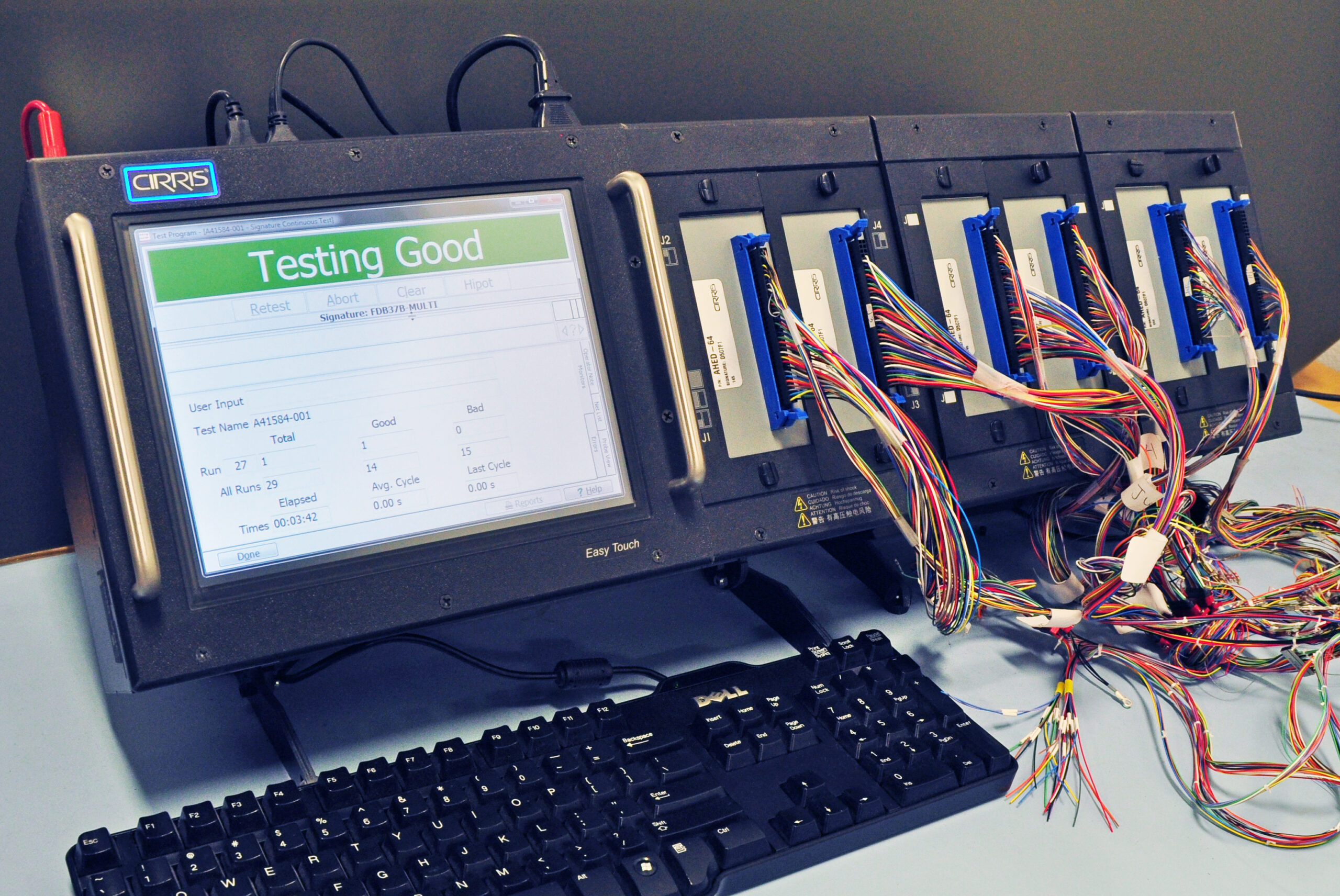

Test Capabilities

ELECTRICAL TESTING Standard test protocols include

insulation resistance, transfer impedance, dielectric withstanding voltage,

high-altitude immersion, partial discharge, operating voltage, shielding

effectiveness, and others.

MECHANICAL TESTING Industry qualification standards include

insert retention, crimp contact retention, mating/unmating forces, shock,

vibration, bend moment, and others.

SIGNAL INTEGRITY TESTING Including operating frequency,

characteristic impedance, insertion loss, backreflection, near-end crosstalk

and others.

For almost 40 years, Omnetics Engineering team has been

bringing innovation to the connector industry and is now partnering with our

customers to facilitate the integration of miniature electronic connectors into

a variety of closely spaced environments.

Omnetics uses a three pronged approach for the development of custom

connectors. First, we work directly with

the engineers that are developing tightly packed systems to establish

performance and fit requirements.

Second, we develop a solution that takes advantage of the ultra-high

performance Flexpin interconnect system.

By using our proven Flexpin and socket design to make the electrical

connection and modifying the system holding the contacts, we maintain a high

level of confidence that the system will outperform even the most severe

requirements. Third, we take advantage

of our quick turn CAD model Design-to-Fab equipment to develop a solution that

will fit unique customer applications with minimal customizing costs. Even when unique mold tools are required, we

use MUD (Master Unit Die) inserts in our molding machines to keep costs and

lead times down.

Whether you are looking for a just a few unique connectors

to launch a new product line or thousands of specialized interconnects, let us

help you develop a connector that fits your system instead of developing a

system that fits standard connectors.