Omnetics Flex Pin Contact

For nearly 4 decades the Omnetics FlexPin and Socket contact system has been providing an extremely robust interconnection method for micro miniature and more recently nano miniature connectors. These connectors are successfully being used in extreme environments which have no tolerance for failure. Systems that are exposed to severe heat, shock and vibration like navigation electronics in deep well drilling; superconducting systems which operate in temperatures below 1 degree Kelvin; armament systems that expose the connectors to heavy shock loads including some ballistic applications which reach tens of thousands of g’s without contact interruption; space applications which expose the connectors to continuous hot and cold cycles, vacuum conditions and radiation exposure; soldier worn environments requiring minimal weight and maximum sealing capabilities.

The extreme condition heritage of our products is only the first step in establishing the confidence that new program engineers require in order to specify our products in their applications. Our customer’s applications involve complex and expensive systems that can also include the safety of human life. Understanding how our product functions and how it performs under test is a critical stage in designing a successful system. Products that extend the connector industry beyond the D-Subminiature and MIL-DTL-38999 circular connector sizes such as the .050” pitch micro miniature MIL-DTL-83513 and .025” pitch nano miniature MIL-DTL-32139 utilize a reverse gender contact system. For larger connector sizes, the female socket is the spring member and the male pin is the rigid member. Once the pitch of the contacts reaches .050” and smaller, the spring member becomes the male pin and the rigid member is the female socket. This allows the socket to become an integral part of the flexible pin structure.

The military specifications for these miniature connectors established a standard socket design and allowed connector companies to develop their own flexible pins to mate with the uniform socket. Two types of male contacts have emerged over the years. The twist pin and the stamped and formed pin. All types of contacts which have been qualified to the Mil Specs have met the requirements laid out in those specifications. There are some differences in the designs which are noteworthy.

The twist pin relies on either precious metal wires or wires that are plated after the contact has been assembled. The typical pin has a number of wires bundled around filler wire and welded at the tip. The other end of the wires are crimped and then twisted and bulged. Wires or board mount leads are also crimped to the back of the contact sleeve completing the contact assembly. This design results in a complex system of welds and crimps which add cost, variability and vulnerability. When the twist pin contact enters the socket, the bulged wires must be compressed to fit inside the socket. This compression of the wires requires a significant amount of force so when many contacts are used in the connector that force becomes substantial. That is why any latching version of connectors with this style of contact require a modified low force pin variant which uses less wires in the contact or less deflection of the wires.

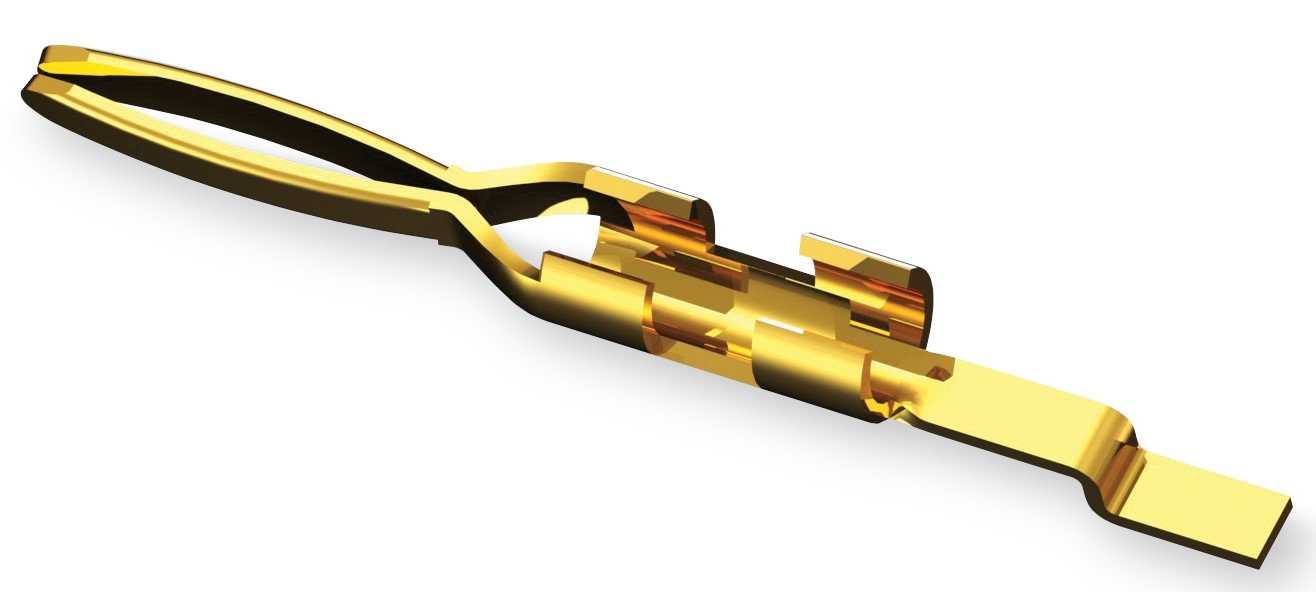

The stamped and formed contact is typically made from beryllium copper and can be plated after stamping and forming leaving no raw edges on the contact. Not all stamped and formed contacts use the same design. Some contacts use three tines (left image) which when viewed from a cross section across the contact points are formed into a smaller radius than the inside radius of the female socket. This results in three specific points of contact. These tines are relatively short in flex length which also results in a high spring force but not a lot of tolerance for dimensional variation. What makes the Omnetics Flexpin unique is that it uses two tines which, when viewed from a cross section across the contact points have a larger radius than the inside radius of the socket. This feature creates 4 redundant points of contact inside the socket. Additionally, when the tines are deflected while entering the socket, the contact edge of the Flexpin generates wipe as it slides across and into the socket. The length of the beams on the Flexpin are also substantially longer than those of the 3 tine versions. This increases the deflection of the tines, reduces the force during insertion and allows more consistent contact forces within the socket dimensional tolerances.

The Omnetics Flexpin, like all male pins on these miniature connectors is recessed in a contact cavity in the plastic insulator of the connector. This offers the Flexpin protection from damage prior to mating the connector system. Once the mating female connector engages with the Flexpin, the tapered and radiused tip of the tines enter into the socket. When this happens any micro misalignment of the tip of the tines disappears and the tips are brought together supporting each other and creating a dually supported cantilever beam which is the heart of the contact system. The two tine beams create four redundant contact points on their edges which are captured within the socket and maintain excellent electrical connection even when monitoring nanosecond interruption rates at extreme vibration levels in multiple axes.

Omnetics has hundreds of millions of Flexpin contacts in continuous operation around the globe and around the solar system. Many of our customers evaluate the product prior to designing it into their systems but few of them are authorized to share the data with us. We do know the generalities of the conditions that the connectors are operating and are free to share that information with our customers. We also have performed testing on our own to gain qualification to the Mil Specs which has put us on the “Qualified Products List” maintained by the Defense Logistics Agency. Summaries from that qualification testing and full reports are available to our customers. We encourage our customers to review the testing we have available. Omnetics also has a generous sample program to allow customers to evaluate our connector performance based on their specific system requirements.