SMT and High Density Connectors

Starting with Micro-D Connectors in a New Era

Today’s circuits are used in applications that require high quality rugged performance, portability, and lighter and smaller components. Surface-Mount Technology (SMT) for components is a significant method on PC boards and is now being pushed further for connector and interconnect methods. In addition, newer circuits are expected to perform during or after exposure to high moisture and a wide range of temperatures. Many new applications also require increases in the number of signal lines than older circuits. The SMT chips are increasing circuit speed and moving to digital, but running on lower voltage and current levels. The applications are also demanding lighter weight, more portability, and high-use reliability. Circuit modules in those applications are being crammed together from module to module while meeting form, fit, and function to meet extreme combination of demands. The Micro-D connector still serves as a major contributor to the industry within the interconnection systems. More often, circuits only require less than one ampere of current for signals running less than 15 volts. Chips are often on modules crammed into tight spaces or out at the end of a probe or module. Signal speeds are also creeping up. One key solution is the Micro-to-Nano interconnect system. That is, the larger Micro-D connector acts as the interface to a system on the edge or outside of the box and is then connected to one or more Nano-D connectors inside the circuit system. Critical to the system is the Micro-D’s ability to handle the outside environment, and the match of proper cabling to the Nano-D connectors at each individual module inside the box.

Big problems can arise as the quantity of signals increase, the speed of the signals increase, and the space available decreases. Electromagnetic interference (EMI), or electrical noise, begins to build in the design and then methods such as shielding, or shunting must be used to protect neighboring systems within the box. The keys to higher speed, especially in digital circuits, are impedance and attenuation control. Signal rise-time can be slowed or digital signal height can be reduced that would cause low circuit performance (similar to seeing pixels on digital TV when the signal is low). Managing the design of the link from the Micro-D into the rest of the system is critical. With today’s solid modeling and fast turn shell manufacturing, a Micro-D connector can be quickly designed and built to mount in crucial points in the instrument. Micro-D back-shells and shielded cable systems are designed to match the impedance of the circuit and shielded or drained to retain high performance in key applications.

Standard military designs in applications such as rocket launchers can now use Micro-D designs to meet the rugged environment while consuming low space on the release pod. Break-away cables can be placed into robotics and remote systems. Micro to Nano systems are used to help control UAV technology that require the larger Micro-D as a ground interface, but has only room for Nano-D connectors inside the systems.

Best designs are beginning to look at standard Micro-D designs as a beginning building block, but with an eye to modified shells for custom fit into the ever increasing complexity and density of remote and portable electronics used in remote control technologies. The Nano-to-Micro cable harness system is becoming more often the final choice to fit all into-the-box.

One key solution is the Micro-to-Nano interconnect system. That is, the larger Micro-D connector acts as the interface to a system on the edge or outside of the box and is then connected to one or more Nano-D connectors inside the circuit system. Critical to the system is the Micro-D’s ability to handle the outside environment, and the match of proper cabling to the Nano-D connectors at each individual module inside the box.

Big problems can arise as the quantity of signals increase, the speed of the signals increase, and the space available decreases. Electromagnetic interference (EMI), or electrical noise, begins to build in the design and then methods such as shielding, or shunting must be used to protect neighboring systems within the box. The keys to higher speed, especially in digital circuits, are impedance and attenuation control. Signal rise-time can be slowed or digital signal height can be reduced that would cause low circuit performance (similar to seeing pixels on digital TV when the signal is low). Managing the design of the link from the Micro-D into the rest of the system is critical. With today’s solid modeling and fast turn shell manufacturing, a Micro-D connector can be quickly designed and built to mount in crucial points in the instrument. Micro-D back-shells and shielded cable systems are designed to match the impedance of the circuit and shielded or drained to retain high performance in key applications.

Standard military designs in applications such as rocket launchers can now use Micro-D designs to meet the rugged environment while consuming low space on the release pod. Break-away cables can be placed into robotics and remote systems. Micro to Nano systems are used to help control UAV technology that require the larger Micro-D as a ground interface, but has only room for Nano-D connectors inside the systems.

Best designs are beginning to look at standard Micro-D designs as a beginning building block, but with an eye to modified shells for custom fit into the ever increasing complexity and density of remote and portable electronics used in remote control technologies. The Nano-to-Micro cable harness system is becoming more often the final choice to fit all into-the-box. Micro-D Upgrades that still meet the Military ruggedness and quality standards include the Latching Micro-D connector family. Quick latches for plug to socket mating has been installed in many new military products and the strength of latching as well as performance in shock and vibration testing exceeds requirements specified for the old jack-screw methods.

Micro-D Upgrades that still meet the Military ruggedness and quality standards include the Latching Micro-D connector family. Quick latches for plug to socket mating has been installed in many new military products and the strength of latching as well as performance in shock and vibration testing exceeds requirements specified for the old jack-screw methods. Omnetics’ Micro Circulars

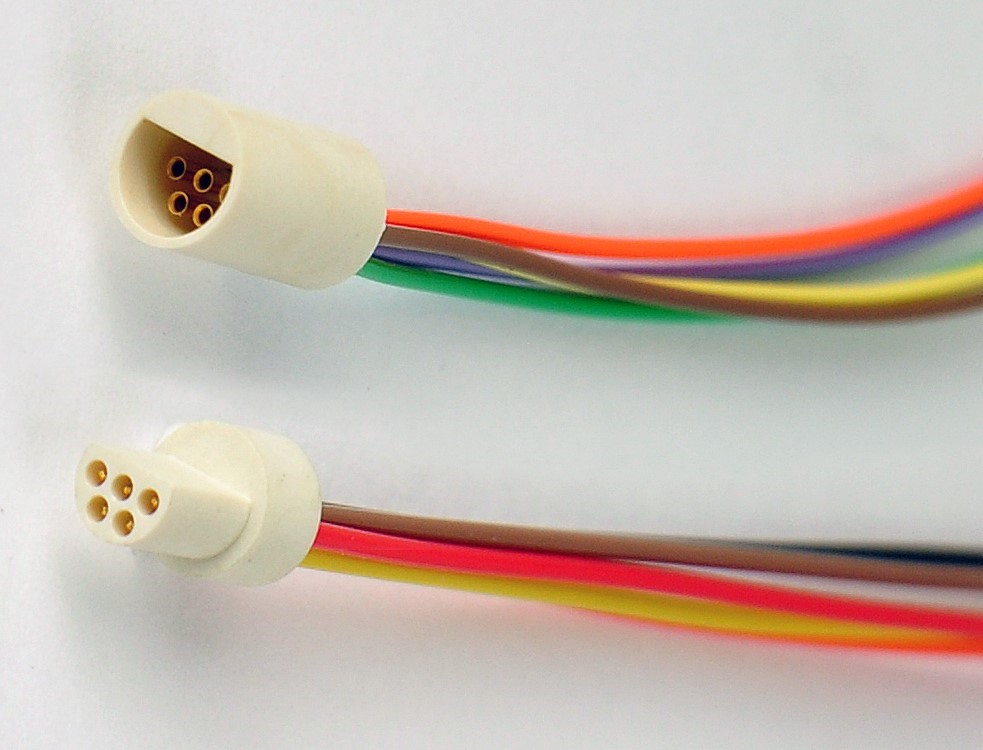

Omnetics Micro 360™ Circular Series (Spaced on .050” / 1.27 mm centerlines) is ideal for tight spaces and rugged environments, featuring a mated length of less than 12.4 mm. Both the male and female contacts are shrouded by the plastic insulators which houses the contacts ensuring that the contacts are protected both during mating and de-mating.

Like all of Omnetics core products, Micro 360’s performance starts up front with the contact system itself. Omnetics gold plated Beryllium Copper flex pins contacts are capable of over 2,000 mating cycles. The insulators are available in 5, 7, 12, 16, 27 and 39 pin configurations, while the connectors themselves are available pre-wired, soldercup, and solid straight thru-hole. The insulator is comprised of LCP (Liquid Crystal Polymer).

Within this product family Omnetics has included (5) distinct, yet similar groups of connectors ranging in contacts from 1 to 39 pins/sockets, with the standard insulator sizes of 5, 12, 16 and 27 and 39.

The Standard (MCP/MCS) Series

The Standard Series, like all (5) versions, utilizes Omnetics’ rugged and reliable flex-pin contact system. These extremely small outer diameters range in size from .220” (5.59 mm) to .445″ (11.30 mm) making Omnetics circular series ideal for routing through tight spaces. With the ability to withstand high levels of shock and vibration while maintaining their electrical integrity, these connectors are ideal for the most demanding applications. Latching options as well as disposable plastic clips are available to ensure Omnetics circular series thrives in some of the harshest environments it faces. Omnetics also offers more ruggedized options, featuring a metal housing, allowing for an environmental seal. Metal versions are available in: Threaded, a quarter-turn bayonet, keyed breakaway as well as a triple-acme start ratcheting option. When combined with a jacketed cable, these connectors are available with a water tight IP68 seal.

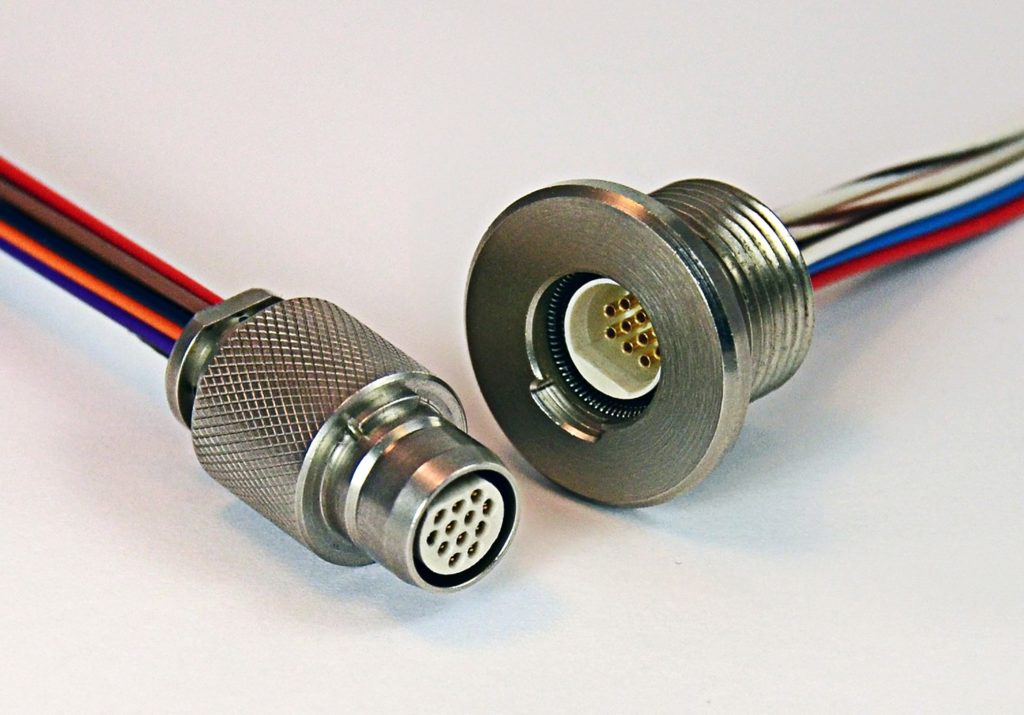

The Threaded (MMCP/MMCS) Series

Omnetics Micro series of circular connectors are also available in threaded metal housings giving them a positive lock and environmental seal. These connectors can be configured with different levels of waterproof sealing up to IP68. A variety of shell materials and finishes are available including nickel plated brass and stainless steel. Environmental and EMI sealed panel mount options (Front, Rear and Protruding) are also available.

The Break Away (BAMP/BAMS) Series

Omnetics Micro series of circular connectors are also designed in a break away configuration. With the ability to withstand high shock and vibrations while maintaining their electrical integrity, the breakaway feature is ideal for the most demanding applications where size and ruggedness are valued. Designed with an extra retention spring, these connectors are engineered to release (break away) at a pre-determined force. These connectors are also available with added waterproof sealing up to IP68 for the mated pair. Utilizing a military quality contact system these connectors are ideal for applications where size, weight, and overall reliability are critical.

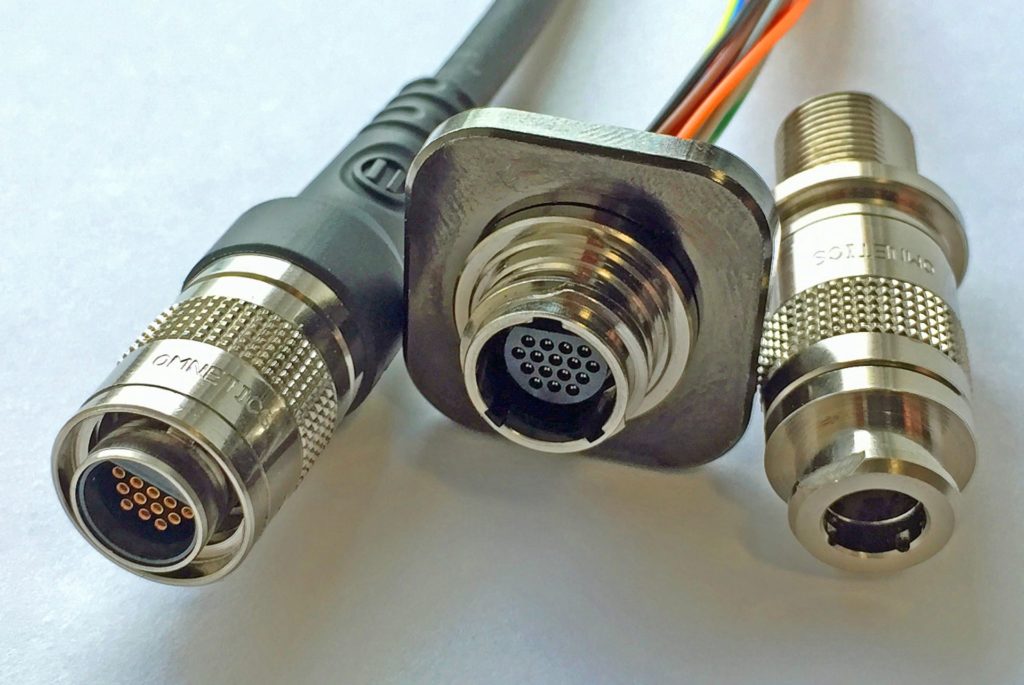

The Twist Lock (TMCP/TMCS) Series

Similar to the Breakaway (BAMP/BAMS) Series, Omnetics Twist Lock series also features miniature quick connect/disconnect characteristics. Omnetics ‘Twist Lock” Micro circular features two bayonet lugs on the male housing; enabling mating and de-mating to be achieved with a simple quarter turn of the female coupling nut. A variety of shell materials and finishes, as well as IP68 and panel mount options, are available upon request.

Micro ACME Triple Thread Ratcheting Shell (RMCP/RMCS) Series

Omnetics latest release into this product family features a familiar feel for those used to working with MIL-38999 circular configurations. This new Ratcheting option includes threaded couplings that encompass metal alignment keys and insulators for quick alignment and mating, even while wearing gloves. The feel of the ratcheting process assures the installer that connections are positive and tightly mated. Nickel plated aluminum shells assist blind mating with first-touch alignment. This new hardware option allows designers the ability to pivot away from larger Mighty Mouse type footprints, to a smaller, lighter form factor without jeopardizing their need for high signal integrity and rugged reliability.

Micro circular connectors are a popular interconnect solution, and they are being used anywhere from the battlefield to the operating room. Connector contacts are from Omnetics’ line of military standard MIL-83513 pins and sockets, and they are plated with military-quality nickel and gold for extended use. Larger contacts types (Size 20 and 23) are available for designers looking to push both power and signal in the same footprint. Metal shells and EMI shielding can also be specified, as well as varying cable types for standard hook-up to differential signal systems. Initial pin counts and shell sizes vary to offer a wide range from 5 to 39 pins. Omnetics offers rapid solid modeling for designers with no time to burn.

Whether your solution is plastic and/or metal housed, these high density circulars have the ability to withstand high shock and vibrations while maintaining mission critical electrical integrity. Many standard and custom options are available including bulkhead mounts, cable harnesses, specialty metals and plating. Let Omnetics help with your next product design.

Omnetics’ Nano Series Offers High Reliability and Portability

As designers of Micro miniature and Nano miniature connectors can all agree, customers’ requirements and expectations have grown. However, their physical footprints have shrunk. Nowadays miniature wire harnesses and connectors are increasingly being re-designed to not only be smaller, but lighter and considerably more rugged as well.

As designers of Micro miniature and Nano miniature connectors can all agree, customers’ requirements and expectations have grown. However, their physical footprints have shrunk. Nowadays miniature wire harnesses and connectors are increasingly being re-designed to not only be smaller, but lighter and considerably more rugged as well.

Within this new trend towards miniaturization, electronics in general are finding themselves on the move. Portable electronics are here, and engineers are being tasked with the effort of not only making their electronics smaller and lighter, but more aesthetically pleasing as well. This shift in technology has forced many design engineers out of their comfort zone as new applications are demanding reduced space for interconnections, as well as smaller, yet more flexible wiring solutions. To stay ahead of the curve, Omnetics’ continues to add to and improve its Nano connector line to meet today’s ever-changing design requirements.

Dating back to the 1980’s,  Omnetics Connector Corporation has been an industry leader as it relates to Nano-miniature manufacturing and design. For decades, legacy products such as single and dual-row strip configurations have aided design engineers searching for size and weight relief without jeopardizing the need for high reliability. Nano strips offer users an extremely low profile package that is well suited for pick and place methods. Omnetics’ Nano connectors have a very tight pitch of .025” (.64 mm) centerlines, and like all of Omnetics Connector solutions, feature Omnetics’ highly reliable gold plated Flex Pin contact system, conforming to the requirements of MIL-DTL-32139. These connectors are available in standard sizes in either single or dual row form, ranging from 2 to 80 positions, as well as custom configurations.

Omnetics Connector Corporation has been an industry leader as it relates to Nano-miniature manufacturing and design. For decades, legacy products such as single and dual-row strip configurations have aided design engineers searching for size and weight relief without jeopardizing the need for high reliability. Nano strips offer users an extremely low profile package that is well suited for pick and place methods. Omnetics’ Nano connectors have a very tight pitch of .025” (.64 mm) centerlines, and like all of Omnetics Connector solutions, feature Omnetics’ highly reliable gold plated Flex Pin contact system, conforming to the requirements of MIL-DTL-32139. These connectors are available in standard sizes in either single or dual row form, ranging from 2 to 80 positions, as well as custom configurations.

If the Nano strips aren’t small enough for your design template, Omnetics has also rolled out their smallest Nano yet: the Polarized Nano Series (PZN). This new interconnect option was built and tested using military style Nano pins and sockets, just like Omnetics Nano strips were designed. Omnetics flex pin technology is utilized to maintain high flexibility and low contact resistance which is vital within the interconnect world. The connectors contact spacing is set at 25 one-thousandths of an inch, and uses both the male and female contacts within the same insulator design, creating a polarized feel without the need for additional polarizing features. Just like Omnetics existing Nano strip options, the PZN series is also available in SMT, thru-hole, and pre-wired form factors. Typical wiring is accomplished using 32 AWG Teflon® insulated multi-strand copper wire rated for up to 1 ampere of current.

If the Nano strips aren’t small enough for your design template, Omnetics has also rolled out their smallest Nano yet: the Polarized Nano Series (PZN). This new interconnect option was built and tested using military style Nano pins and sockets, just like Omnetics Nano strips were designed. Omnetics flex pin technology is utilized to maintain high flexibility and low contact resistance which is vital within the interconnect world. The connectors contact spacing is set at 25 one-thousandths of an inch, and uses both the male and female contacts within the same insulator design, creating a polarized feel without the need for additional polarizing features. Just like Omnetics existing Nano strip options, the PZN series is also available in SMT, thru-hole, and pre-wired form factors. Typical wiring is accomplished using 32 AWG Teflon® insulated multi-strand copper wire rated for up to 1 ampere of current.

Omnetics Nano strip family of interconnect solutions are ideal and tough enough for some of the harshest environments on planet Earth and beyond. From deep space explorations, medical electronics, battlefield equipment, robotics and so much more, Omnetics connectors continue to prove their worth day after day when second chances aren’t an option.

From the Engineer’s Desk: High Speed Connector Design

Part XIV – EMI Shielding in Connectors

This article is a continuation of our series on connector design. In this installment, the focus will be on connector shielding.The Purpose of Shielding

Shielding is a critical consideration for many of today’s cable/connector assemblies. The purpose of shielding is to minimize or eliminate the transmission of electromagnetic interference (EMI) both into the cable (from external signals) and out of the cable (from internal signals).Cable Shielding

Shielding the connector is irrelevant unless the attached cable is shielded, so a discussion about connector shielding must consider the cable. The most common types of cable shields are braided shields, foil shields, and a combination of braided and foil shields. Braided shields have good flexibility and flex life but cannot achieve 100% shielding effectiveness (typical effectiveness is between 80% and 95%). Foil shields have excellent shielding effectiveness—up to 100%—but have poor flex life that can often lead to shield cracking. For these reasons, often times the best solution is to use a braided/foil shield combination.

Shielding the connector is irrelevant unless the attached cable is shielded, so a discussion about connector shielding must consider the cable. The most common types of cable shields are braided shields, foil shields, and a combination of braided and foil shields. Braided shields have good flexibility and flex life but cannot achieve 100% shielding effectiveness (typical effectiveness is between 80% and 95%). Foil shields have excellent shielding effectiveness—up to 100%—but have poor flex life that can often lead to shield cracking. For these reasons, often times the best solution is to use a braided/foil shield combination.

Connector Shielding

The shielding of the connector is sometimes an afterthought. If the cable is shielded, it is sometimes assumed that the shielding the connector is unimportant. However, shielding the connector is just as important as shielding the cable. The connector’s role is to prevent EMI and provide a continuous path for any shield currents. If there is no path, the currents have no way to exit the shield, and signals will radiate into and out of the cable.

One important consideration with regard to connector shielding is whether to use a metal housing. For low frequency and less sensitive applications, a metal housing may not be necessary. If a metal housing is not used, it remains critical to connect the shield through the connector. This is most often achieved by connecting the shield through a connector pin. For higher frequency and more sensitive applications, a metal housing should be used. If a metal housing is used, the shield should be connected to the housing with a band clamp. Finally, additional braided or foil shields can be considered for maximum coverage.

is sometimes an afterthought. If the cable is shielded, it is sometimes assumed that the shielding the connector is unimportant. However, shielding the connector is just as important as shielding the cable. The connector’s role is to prevent EMI and provide a continuous path for any shield currents. If there is no path, the currents have no way to exit the shield, and signals will radiate into and out of the cable.

One important consideration with regard to connector shielding is whether to use a metal housing. For low frequency and less sensitive applications, a metal housing may not be necessary. If a metal housing is not used, it remains critical to connect the shield through the connector. This is most often achieved by connecting the shield through a connector pin. For higher frequency and more sensitive applications, a metal housing should be used. If a metal housing is used, the shield should be connected to the housing with a band clamp. Finally, additional braided or foil shields can be considered for maximum coverage.

Key Principles to Consider

In order to determine an optimal shielding strategy for each specific application, there are two principles to consider:- Shielding requirements increase proportionally to signal frequency. As a general rule, signals in the low Megahertz may not require a robust shielding strategy. Simply connecting the shield through a pin may be sufficient to meet your application’s requirements. For signals above approximately 100 MHz, it is recommended that the shield is connected through a metal housing, and signals above 1 GHz should use multiple shields (braided and foil) to eliminate any potential EMI.

- Shielding effectiveness is inversely proportional to the largest shield opening. Considering this principle provides engineers with a very simple and practical first-order approximation of the shielding effectiveness of their assembly. As a general rule, openings should be limited to about 0.500” for 100 MHz signals, and 0.050” for 1 GHz signals.

Conclusion

Shielding is an important variable to be considered when designing a cable/connector assembly. It is important to understand the effectiveness of different shielding strategies. Using the principles outlined in this article, engineers can be equipped with a general understanding of when to consider these various strategies.Did you know?

There are three main groups of satellites:

- Fixed satellites transmit voice, video, and data information

- Mobile satellites are used for navigation (GPS) and connecting remote shifts and aircrafts

- Scientific research satellites transmit meteorological, land, and other scientific information

See Omnetics’ products optimized for satellite and space here.

Calendar of Events

29-30

UK Security Expo

Location: London, UK | Booth: #C3712-14

Future Soldier Technology

Location: London, UK1-4

Offshore Technology Conference

Location: Houston, TX

21-24

SOFIC

Location: Tampa, FL