Connectors for portable military and high-density ranging and detection systems are set to influence the broader connector market as they lead the way for high speeds, small sizes, and light weights.

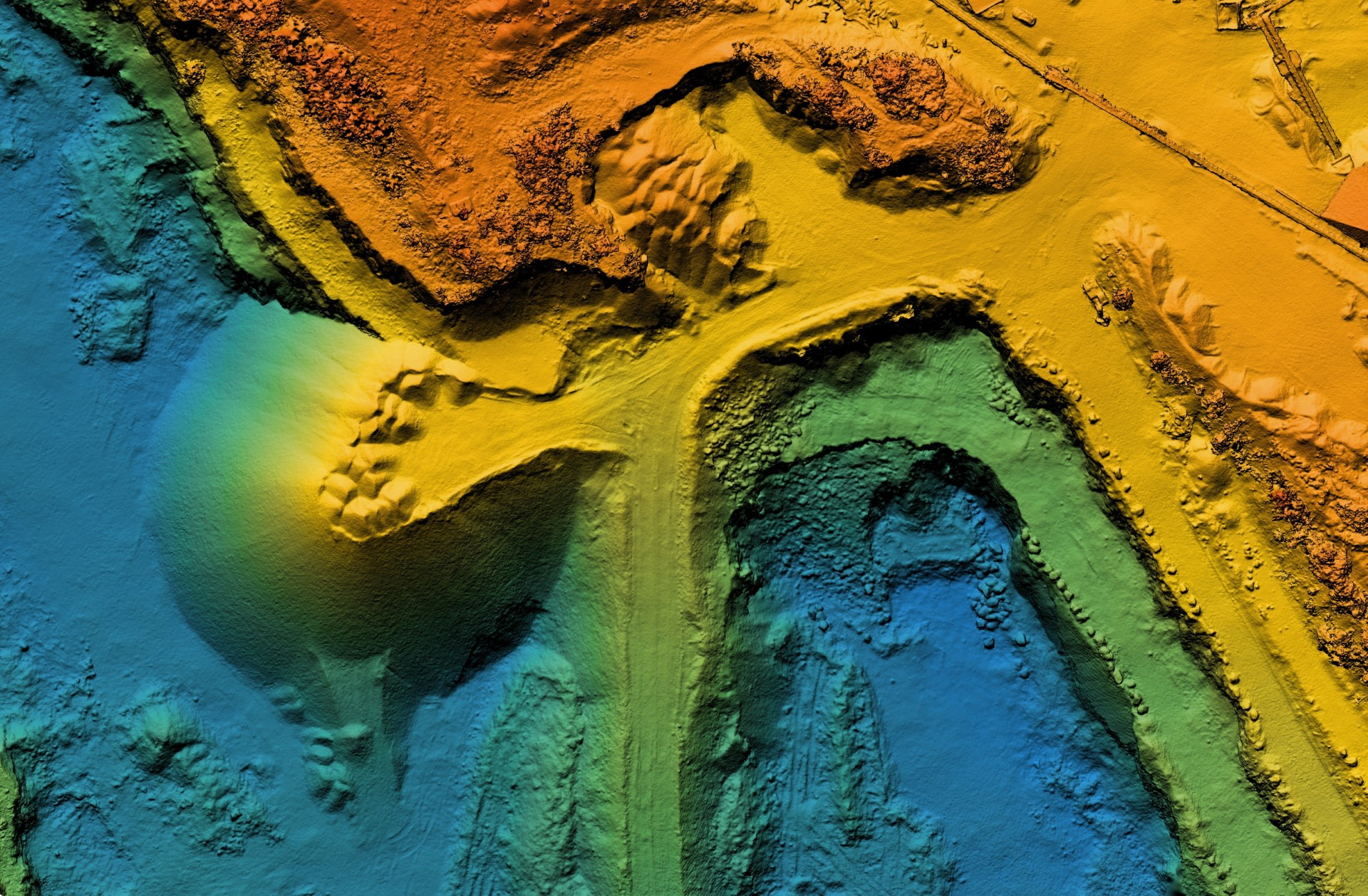

High-resolution multibeam LIDAR map showing faulted and deformed seafloor geology. (NOAA Ocean Exploration & Research)

LIDAR, which stands for light detection and ranging, is a remote sensing technology that uses light in the form of a pulsed laser to measure the distances between a transmitter and a target item or area of interest. LIDAR offers two key advantages: Light travels at extremely high speeds — one million times faster than sound/sonar — and it can focus on a single specific object. By comparison, RADAR, or radio detection and ranging, operates at a very low frequency, providing much lower focal capabilities and detection limits.

LIDAR systems are also relatively simple, including a laser, a scanner, and an electronic reference, such as a soldier’s current position or a reference to a GPS receiver. Another key advantage over general optical scopes and older laser detectors is LIDAR’s superior accuracy and its ability to see through masking items, such as leaves, trees, and even camouflaged netting. LIDAR systems can feature high spatial resolution due to the small focus diameter of the beam, which benefits from a higher pulse repetition rate. Military drones and larger UAVs employ LIDAR to site, collect, and transmit data back to a command station. Some items under surveillance are in motion, requiring “tracking electronics” to be added to LIDAR systems similar to older radar gun-fire-control electronics. In addition to LIDAR pulse-and-firing control systems, designers have also added display monitors and data processing computers.

Portability and ruggedness are also primary design concerns for many of these new military surveillance and distance-measuring systems.

Military LIDAR

To retain portability, manufacturers such as Extreme Engineering Solutions (X-ES) offer a family of instruments to integrate command, control, communications, computers, intelligence, surveillance, and reconnaissance applications, also known as C4ISR.

LIDAR instrument packs require high-density connectors within the circuit boards, as well as small and flexible cable routing to various signal, power, and display data from module to module. These connectors must be small, rugged, and offer easy in-field connectivity, and must also be easy to align and key, even for gloved soldiers in battlespace environments.

Latching micro connectors

Micro-circular connectors are being especially designed to meet these demanding criteria. Multiple pin sets are small enough to handle the newer electronics and typically use 24 to 26AWG Teflon® insulated wiring. Nearly automatic alignment and quarter-turn latching enable quick mounting in portable instruments and hold tight through the shock, vibration, and other environmental extremes often experienced in military applications. For covert surveillance cases, these connectors can be also plated in dark black to avoid light reflection and detection.

Nano coax connectors

When designing for LIDAR applications, one must first define which application and light frequency provides the best data. Wavelengths most often include applications spanning the infrared frequencies through the visible light range and beyond. Board designs using higher frequencies and shorter wavelength systems will need to include coaxial cable in some portions. When light weight and portability is required, nano-coax systems may be the best choice. These systems offer low size and weight, but easily obtain the key elements of microwave signal control. Nano-coax systems should be fully tested with board launch mechanisms designed to capture the various gigahertz (GHz) signals passing through. Pre-tested board modules are best for performance and protocol management. To avoid problems in the field of service, tightly locked and mated nano-coax is critical. Many button-type coax exist for up to 2–3GHz, but they rarely survive active travel on military vehicles.

X-ES processor

Military portable and surveillance systems are carried into the field for use at command stations. These base stations, as well as those in satellites, must be able to handle the higher signal volume produced by LIDAR systems while retaining signal integrity. Single-unit processing systems, such as those from X-ES, are built to fit into large modular stations, but remain compact and intact during field performance.

NASA scanning module

Much of our military definition and ranging data comes from satellites, as space-mounted LIDAR systems can easily see and define items through forest canopies. By using multi-spectral light systems, such as infrared images overlaid on the visual or higher frequency spectrum, command centers can identify key target images, track them as they move, and, when used in combination with GPS data, even plot the key image direction, rate of travel, and possible destination. The design of the cables and connectors employed in military-type satellites is critical, just like those designed for portable military equipment.

Resistance to environmental hazards, low weight, and small size are all qualities of paramount importance. Ensuring continuous signal integrity during high shock and vibration also depends on effective mounting methods that fit the space module. Oftentimes, these cables must be exceptionally flexible as well as shielded to protect from electromagnetic interference (EMI). Signal noise may escape from LIDAR cables in both directions, and nearby circuits are liable to add sparkle and image problems with the image display processor boards.

Interconnects in space systems must use materials that meet the NASA specifications for outgassing. Space-rated micro- and nano-connector systems employ approved liquid-crystal polymer (LCP) insulators and adhesives. In order to survive the many orbits of a satellite, components and instruments must also withstand significant temperature changes and potential exposure to dangerous gasses, like chlorine, that can escape and would destroy any commercial-rated silicone chips in the system. Commercial connectors are rarely exposed to these conditions; so, although they offer good performance on Earth, it is critical that they not be employed in space applications.

High speed Nano Connectors

As military technologies evolve, more connector and cable systems are being rapidly designed and adapted to the many new formats needed. Designers should consider standard connectors during initial phases because they are easily converted to meet specific performance demands. For instance, signals are changing from digital to analog, circuit speeds are ramping above 2Gb/s and on beyond 10Gb/s, and photon signal management is enhancing performance and protecting devices from cyber intrusion.

Connector designers can change standard connectors to meet these and other new performance needs. Most connector designs are institutionalized inside computers, most of the materials and processing methods needed already exist, and solid modeling can offer quick adaptations to meet new technologies. The connector industry is experiencing the push for smaller, more rugged, and more portable electronics, so the connectors and cables that enable them continue to become smaller and more robust and circuit chips continue to run on lower voltages and use less current. In response, rapid designs and design adjustments are being done every day. We are living in an era of application-specific connector and cable systems and, as our military and high-tech industries continue to push the leading edge, and other segments see how easy it is, these processes will normalize throughout the connector industry.